How is cheese made? At Studer it takes knowledge, skill, and passion

Our cheese production

We keep a tight hold on the whole value chain – from cow to cheeseboard. We are always on the lookout for the “X” factor, without moving away from our roots and the art of traditional cheesemaking. We unite creativity with experience, and passion with specialist knowledge. We are continually developing ourselves and our products. Just like our cheeses, we let our ideas mature to make sure the final product is utterly convincing – and tastes great. We are Original. Different. And so is our cheese. This is what makes us who we are – and we’re proud of that.

Milk processing

Our farms are located close by and deliver fresh milk to us daily. We then test it. This involves both head and heart, because, when it’s all about the finest quality, we make zero compromises. After quality checks have been carried out we set the fat content and the correct milk temperature to produce the respective specialty cheese. After adding lactic bacteria and rennet the milk is ready to be refined into cheese.

Prematuration

Working with cheesemaking equipment requires a skillful touch. We treat every specialty cheese individually. We can obtain different product characteristics depending on the temperature and reaction time. Both the bacterial cultures used and the experience of the master cheesemaker have an important role to play here.

Cheesemaking: Preliminary steps

When the coagulum is firm enough we cut it into pieces using the curd cutter – this produces the curd. Once the desired temperature has been reached we fill the mold with the curd. Now the cheese wheels are pressed. The whey then drains out through the many small holes in the base of the molds.

Lactic fermentation

The cheese wheels now spend several hours in air-conditioned storage boxes. This is where the lactose is converted into lactic acid. The climatic conditions are precisely defined in advance. Our master cheesemakers oversee this microbiological process with great care and attention.

Salt bath

It is now time for the salt bath. Salting is important to enable maturation of the cheese wheels. It promotes stabilization and rind formation. We can therefore ensure that the cheese has a long shelf life and create the conditions for perfect storage and maturation. After one to two days in the salt bath the young cheeses are taken to the maturation cellar.

“Asking a master cheesemaker of Studer specialty cheesemakers about his favorite cheese at a cocktail party, he will answer: «It's the one I haven't invented yet».“

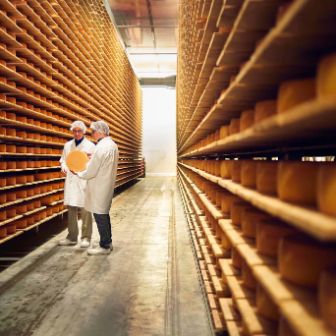

Maturation and refining

Time is the most valuable ingredient. We give our cheese the exact amount of time that it needs to develop its special character and individual degree of ripeness. Our master cheesemakers look after each and every one of the cheese wheels in our air-conditioned cheese cellar with dedication and care. They examine each individual cheese wheel very closely by hand – no matter whether the maturation time takes six to eight weeks, as is the case with «FamilieChäs», or a whole year, e.g. «Der edle Maxx 365».

Quality control

The cheese production process only completes, however, when, following the maturation period, we test the cheese wheel for hole formation, curd quality, flavor, and appearance. All aspects must satisfy our stringent requirements. Only when the cheese passes our quality control one hundred percent is it ready for its grand debut on your plate.